Chicago Fed president Austan Goolsbee and University of Chicago economist Chad Syverson persuasively argue in a new paper that housing construction productivity has followed a “strange and awful path” that cannot be explained with mismeasurement. Using a variety of survey methods, the U.S. Bureau of Labor Statistics measures labor productivity by estimating output per worker at the sector level. In stark contrast to the rest of the economy, construction productivity was forty percent lower in 2020 than in 1970, while productivity has more than doubled in other sectors. It is impossible to solve the housing crisis without accounting for this.

Local regulatory policy certainly interacts with the decline in productivity. Zoning laws, for example, may disincentivize innovation that may otherwise spur productivity growth. Work from FREOPP, particularly from Roger Valdez, has pioneered a modern approach to housing policy that may do much to resolve the housing crisis by simultaneously increasing access to low-income households and allowing greater variety in the types of housing that can be built. Valdez, along with Jon Hartley and Avik Roy, prescribes six government policies to increase the affordability of housing and mitigate the crisis. While freeing up restrictions on local housing supply likely increases affordability, their effect on productivity is at best indirect. Furthermore, it is not clear that freeing up supply alone will be sufficient to resolve the housing crisis if productivity growth does not follow.

Critically, it is not merely that restrictions on housing quantity reduce the supply of affordable housing, but also the allowed method of production. Laissez-faire policy played a key role in the growth unleashed by the Industrial Revolution, but none of that growth would have been possible without the technological innovation induced by mass production methods. Historically, mass production and freedom to innovate in production methods spur rapid growth. Housing production largely lacks this freedom.

For example, consider a good—widgets—that has government-imposed quantity and quality restrictions. Producers can only sell a certain amount of the good at a sufficiently high quality, making the supply of affordable widgets artificially low. Suppose also that the government restricts how widgets are produced, by requiring they can only be made by hand by union-certified artisans. Even if the government abolishes the quantity and quality restrictions, it may not be enough to sufficiently increase the supply of affordable widgets because production method restrictions remain. So long as governments dictate how widgets get made, they effectively limit how many widgets get made. Artisans free to produce whatever quantities they want at whatever quality will still be less efficient than mass production of widgets by factories.

This is precisely the situation faced by the U.S. housing market today. Even with the abolition of zoning laws and well-targeted interventions by the government, housing would remain largely restricted to what experts call “stick-built housing,” when buildings are constructed on-site by traditional construction methods. This method requires highly skilled, frequently unionized workers to produce homes on-site. Pre-fabricated factory-built housing, by contrast, costs about 1/3 as much per square foot, but nevertheless constitutes about 10 percent of new single-family home construction, down from 60 percent in the early 1970s.

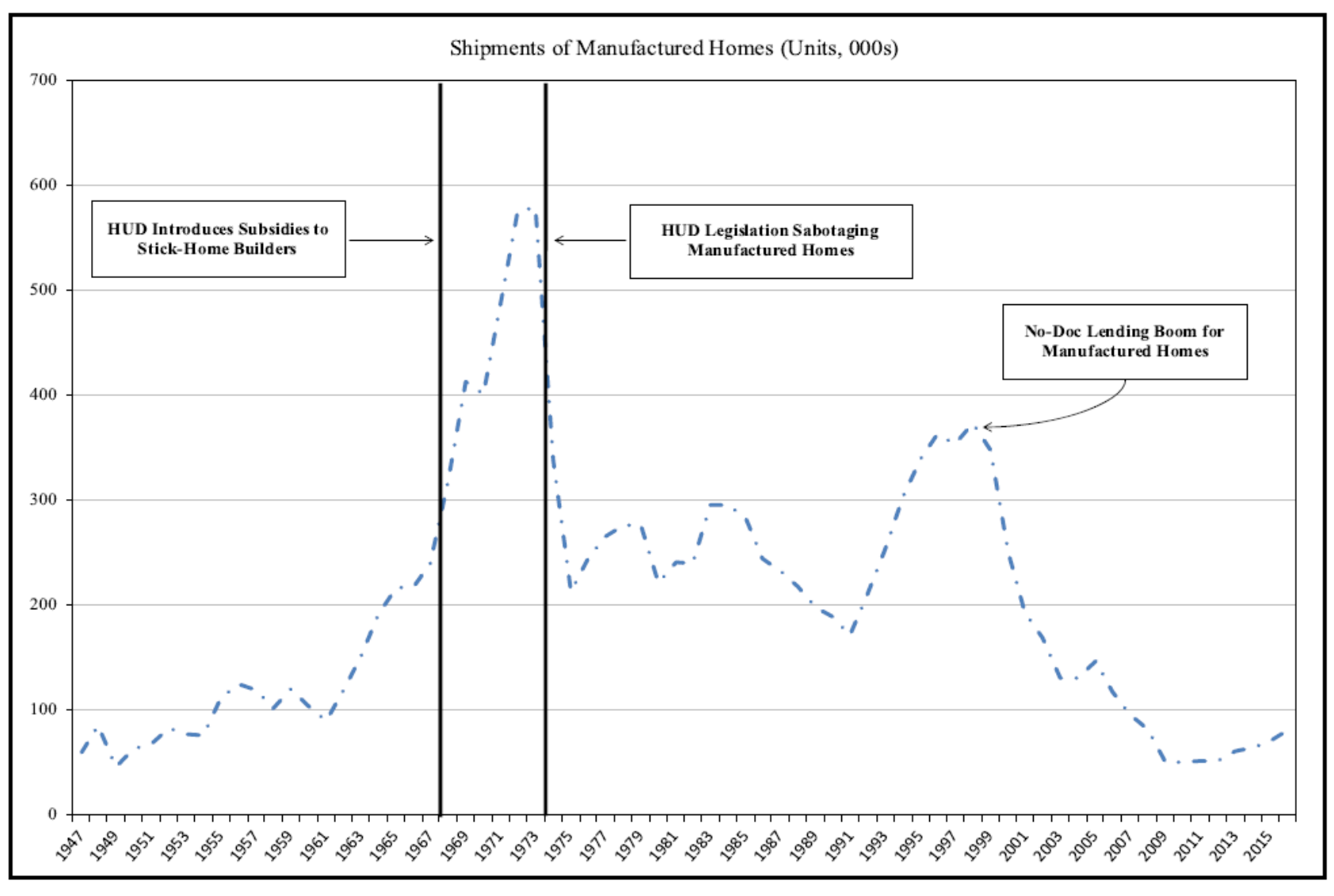

Why the decline? Research by economist Jim Schmitz at the Federal Reserve Bank of Minneapolis highlights that the prevalence of stick-built housing is a function of monopolistic behavior by construction companies and government policy, particularly the National Association of Home Builders (NAHB) and the Department of Housing and Urban Development (HUD). This happened in a couple of steps.

First, HUD developed Section 235 in 1968, a program that substantially subsidized mortgages on stick-built but not factory-built homes. Given the relative inefficiency of stick-built production, this program effectively subsidized a low-productivity technology at the cost of other, more efficient production methods.

Second, HUD and NAHB pushed the National Manufactured Housing Construction and Safety Standards Act of 1974 through Congress. The act effectively operates as a national zoning ordinance and restricts the production of factory-built homes substantially by requiring such homes to meet certain standards. At the time, factory-built housing competed with stick-built housing largely in low-density areas, many of which had no zoning laws to begin with. Before factory-built housing could make headway into urban areas, it was strangled in the crib.

Zooming out, why does this matter for productivity and efficiency? To steal an example from Schmitz, it is as if Toyota is required to assemble a Camry in a driveway rather than in a factory. It is therefore no surprise that housing production is needlessly expensive. It is challenging to think of how, for example, apartment buildings would be factory-built. But that’s precisely the point: restrictions on production methods over the past half-century have restricted the creativity that follows from the freedom to innovate and the productivity growth that follows, leaving us without whatever the housing analog is to the iPhone.

These restrictions on factory-built housing may also affect emerging 21st-century technologies, like the 3D-printed houses pioneered by Austin-based ICON, that promise to further reduce the cost of home construction.

Housing, even with loosened zoning rules, is today stuck with production methods better suited for the eighteenth century. It is time for governments to allow housing construction to regain its place at the forefront of modern industrial production methods. Empirically, this is how we have achieved productivity growth in every other sector of the economy.